-

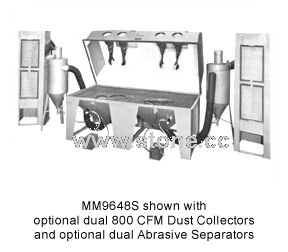

Suction Blasting Series-MM9648S

-

Place of Origin:

China

China

-

Type:

Sawing and Cutting Machinery -

Genre:

Machinery & Equipment -

sCode:

STPR1288954

-

-

Place of Origin:

United States- Suction system dry blasting cabinet systems work by using a high-pressure air line and an abrasive feeder line that both connect to a nozzle or gun type device. Air and abrasive particles are mixed at a ratio of 2 parts air to 1 part abrasive. Media is recycled from the gun system to the hopper and back to the gun system.<br /><br />The applications for a suction system dry blasting cabinet are virtually limitless, including cleaning, deburring, decorating, deflashing, etching, finishing, honing and peening. All of these uses and more can be accomplished easily with quick sweeps of the suction blasting cabinets gun nozzle. Scale, corrosion, old paint and other surface materials are removed in minutes, leaving metal surfaces free of foreign matter and contamination. Even tough mill scale is quickly and efficiently removed.<br /><br />The usual operating pressure for Kramer Suction System Dry Blasters is 85 PSI. These siphon blasting cabinet systems utilize a variety of abrasives such as aluminum oxide, white aluminum oxide, urea and other plastic abrasives, corn cob grit, walnut shell grit, glass beads, pumice, crushed glass grit, silicon carbide, steel grit and steel shot. A multitude of finishes are possible, ranging from a micro-finish to a coarse-grade finish, depending upon the specific media used.<br /><br />The standard cabinets have door openings on the side as well as a large opening in the front. The split-level style is hinged in the center; the entire top half opens to give access to the work stage, somewhat like a clamshell. This has an advantage when handling large heavy parts.<br />SM20b shown with 100 CFM dust collector and optional work stand<br /><br />